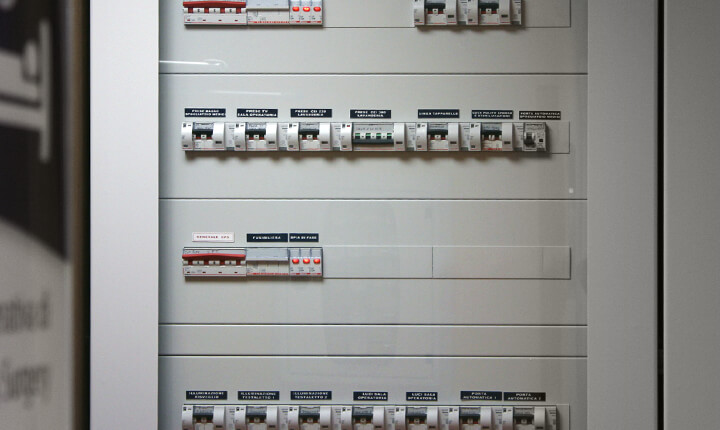

QSO – Panelboards for medical application

The QSO switchboards are specific for powering the electrical systems of rooms used for medical use.

Service continuity guarantee

The QSO switchboards are specific for powering the electrical systems of rooms used for medical use, as required by the CEI 64-8 standard. They provide macro and micro shock protection by means of electrical separation between the user circuit and the network with earthed neutral. They can be installed in rooms for surgery, anesthesia, surveillance or intensive care, but also in dental surgeries or analysis laboratories, having continuity of service is a fundamental necessity.

The accidental suspension of the activity could compromise the outcome of the operation or the health of the patients, therefore it is mandatory to use protection systems that prevent the automatic interruption of the electrical circuits at the first fault. For these circuits, the power supply via an isolation transformer must be adopted as a protection system against the danger of accidental contact.

Maximum security

The QSO switchboards for medical premises are declared "class II electromedical equipment with metal casing" pursuant to article 14.2 of the CEI EN 60601-1 (CEI 62-5) standard. Total selectivity between the feeder and the main switch is guaranteed in each switchgear, thus ensuring continuity of service in the circuits not affected by the fault.

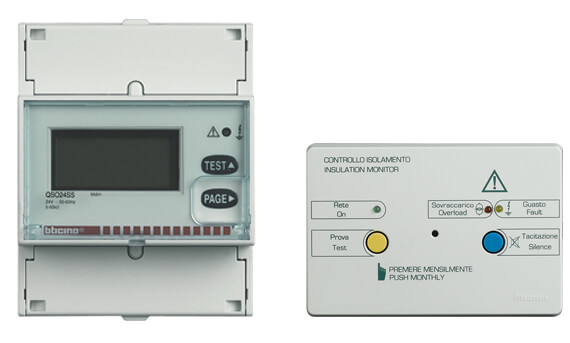

Insulation monitors and repeater panels

Insulation monitors are devices compliant with the 61557-8 Standard, which, in addition to measuring the insulation resistance, also allow the transformer overload and overtemperature control. Repeater panels, on the other hand, are necessary for remote optical and acoustic signaling in the event of a fault.

Isolation and safety transformers

The integrated isolation transformers ensure the electrical separation of the consumer circuit from the network with earthed neutral, preventing dangerous leakage currents in the event of accidental contact. These isolation transformers are equipped with a Pt100 probe, which detects the operating temperature value in the windings, ensuring real-time monitoring of the operating conditions.